Triple-c mold maker, manufacturers quality molds in China

Triple-C was established 15 years ago in Shanghai with the aim of providing not just mold-making and plastic parts molding services but also design, prototyping, and delivery solutions to customers seeking more than a standard mold maker in China.

Compared to other companies or foreign mold makers, we offer additional services and strive for top-notch quality tooling in our mold shop.

We understand the difficulty of finding a good mold maker in China that offers low prices. However, your search can end here. Sourcing is not as challenging as you might think. Simply contact one of Triple-C's sales managers for your inquiry or questions.

While there is intense competition in the manufacturing arena in China and Taiwan, with perhaps 12,000 to 15,000 Chinese mold makers in the market, our mold maker boasts outstanding experience and an innovative mindset.

Here's a little secret: our company was founded by former injection mould makers and designers from the electronics giant, Philips!

what kind of plastic injection molds can we make ?

As you know the general Chinese mold quality is improving these days and we- being an experienced injection mould China manufacturer- can say we are in the top of bringing these quality close to European and Western US standards.

Working with Triple-C, means that you don-not need to supervise the mold design and qualifications yourselves of your tool to make sure you received what you paid for.

Besides mold making our other services are part design and Mold design:

One of our clients made a design of a complicated mechanical system for an agricultural automated machine and asked us to design an innovative family mold for their gearwheels and actuator. It was designed by our tooling and mold designer.

We build 4 new family molds for the first 10.000 test series. Our total cost were much less compared to the rather expensive cost at their local mold manufacturing.

Nowadays these molds have been injection molding these PA parts for some year at an excellent level without any problems or defects..

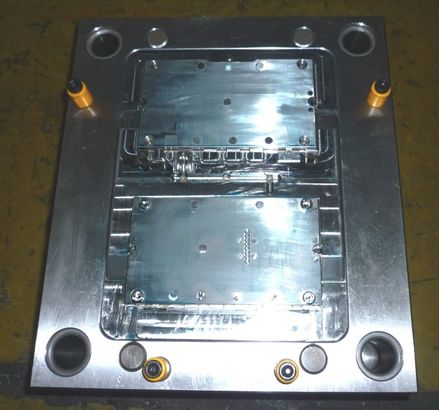

In order to understand the mold making you must understand how a mold is build, and how it looks like, only good Chinese suppliers who want a long term the partnership, will tell you this..

SO-conclusion-: Our mold designers and manufacturers are always available to think together with the customer and to build high quality mold based on years of experience.

Working with Triple-C, means that you don-not need to supervise the mold design and qualifications yourselves of your tool to make sure you received what you paid for.

Besides mold making our other services are part design and Mold design:

One of our clients made a design of a complicated mechanical system for an agricultural automated machine and asked us to design an innovative family mold for their gearwheels and actuator. It was designed by our tooling and mold designer.

We build 4 new family molds for the first 10.000 test series. Our total cost were much less compared to the rather expensive cost at their local mold manufacturing.

Nowadays these molds have been injection molding these PA parts for some year at an excellent level without any problems or defects..

In order to understand the mold making you must understand how a mold is build, and how it looks like, only good Chinese suppliers who want a long term the partnership, will tell you this..

SO-conclusion-: Our mold designers and manufacturers are always available to think together with the customer and to build high quality mold based on years of experience.

|

|

Molds for small to large parts , and from simple to complicated products.It doesn't matter how your product looks or in what quantity you need to manufacturer your part or component: we can make small or medium moulds, and, yes even large molds or molds for some complicated parts with many sliders; but also molds for 2 component parts and family molds.Molds for small, medium and large quantities.If you need an aluminum prototype mold for short run we are also your supplier, with MUD molding and aluminum inserts we are ready for cheap short run injection molding.What about Triple-c 's mold quality and process? |

standard mold construction in China

A basic mold made by Chinese mold makers typically consists of two main parts: an injection side and a locking side. Together, they enclose the cavity or cavities for one or more molded parts. In plastic injection molding, the mold cavity is filled with molten plastic material through sprues and runners. The sprue (and often a part of the mold cavity and runners) is recessed in the fixed mold part (injection side), while the remaining portions are located in the moving die part (locking side or ejection side). Both mold parts are equipped with cooling channels.

On the locking side, a space is created for the ejection mechanism, known as the ejector plates, which are also typically made by Chinese mold makers. This space allows the ejectors to function properly for product ejection. Guiding pins, usually 2 to 4, are provided for precise alignment of the two mold halves, optionally in combination with leader pins.

To ensure the mold parts are always in the correct relative position, a different diameter or an asymmetric position of the guiding pins is employed. The guide pins are preferably placed on the injection side of the mold, so they do not impede the free fall of the product(s) during ejection. With the aid of a centering ring on the injection side of the mold, proper positioning relative to the injection molding machine is achieved.

injection mold making and Sourcing

Sourcing Expertise Beyond Injection Molded Parts at Triple-C Mold Maker

At Triple-C, our expertise goes beyond injection mold making and manufacturing. We understand that many products require additional components beyond just injection molded parts. That's why we offer comprehensive sourcing services to assist you with assembly parts and packaging solutions.

Assembly Parts: The Key to Cohesive Products

We categorize assembly parts as components that form an assembly together with injection molded parts. Our sourcing capabilities cover a wide range of assembly parts, including but not limited to:

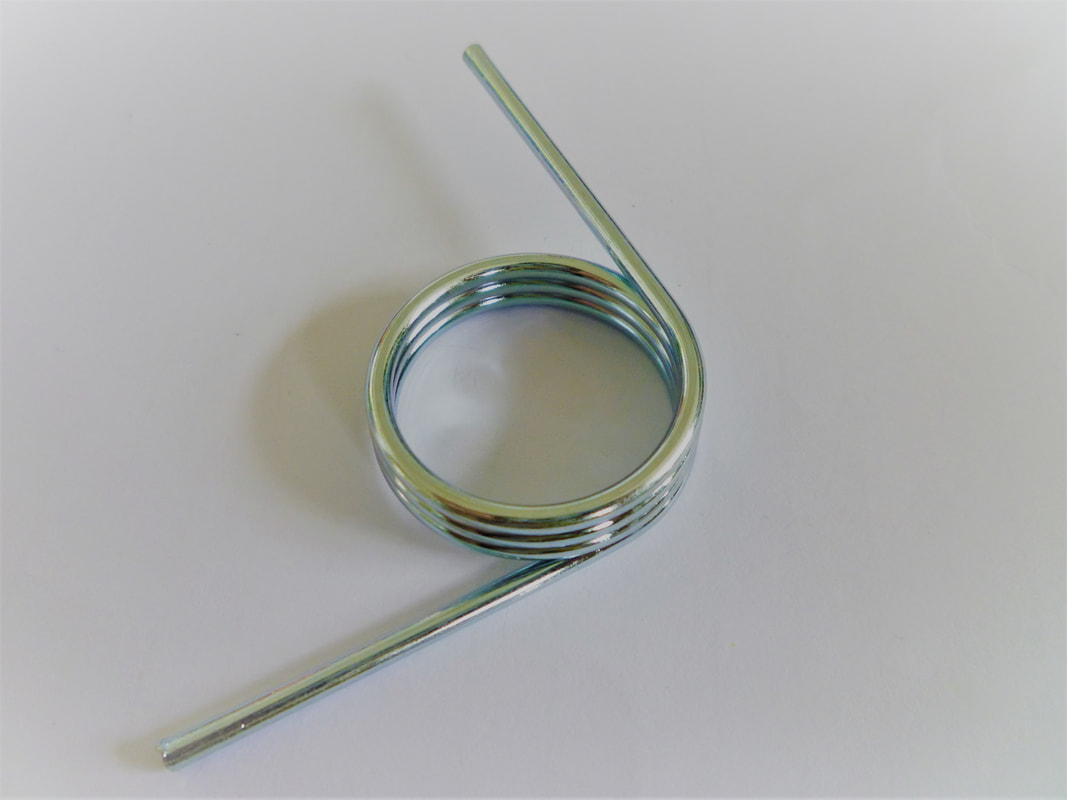

- Torsion or compression springs

- Die-cast aluminum parts.

- Extruded components.

- steel components, think of screws, bolts and nuts, we offer inserts aswell.

Packaging Solutions for Complete Products

In addition to assembly parts, we can source packaging solutions to ensure your products are ready for distribution and sale. Our packaging sourcing services encompass various materials and designs to meet your specific requirements.

Unmatched Convenience and Cost Savings

By offering sourcing services for non-plastic parts, Triple-C sets itself apart from typical injection mold manufacturers in South China and the Shanghai region. We understand the hassle and additional costs associated with sourcing components from multiple suppliers. That's why we strive to be your one-stop solution, saving you time, money, and unnecessary stress.

Trust Triple-C for All Your Molding and Sourcing Needs

When you purchase molds from Triple-C in China, you gain access to our comprehensive sourcing expertise. Partner with us for a streamlined and cost-effective solution for all your injection molding, assembly part, and packaging requirements.

Sourcing Expertise Beyond Injection Molded Parts at Triple-C Mold Maker

At Triple-C, our expertise goes beyond injection mold making and manufacturing. We understand that many products require additional components beyond just injection molded parts. That's why we offer comprehensive sourcing services to assist you with assembly parts and packaging solutions.

Assembly Parts: The Key to Cohesive Products

We categorize assembly parts as components that form an assembly together with injection molded parts. Our sourcing capabilities cover a wide range of assembly parts, including but not limited to:

- Torsion or compression springs

- Die-cast aluminum parts.

- Extruded components.

- steel components, think of screws, bolts and nuts, we offer inserts aswell.

Packaging Solutions for Complete Products

In addition to assembly parts, we can source packaging solutions to ensure your products are ready for distribution and sale. Our packaging sourcing services encompass various materials and designs to meet your specific requirements.

Unmatched Convenience and Cost Savings

By offering sourcing services for non-plastic parts, Triple-C sets itself apart from typical injection mold manufacturers in South China and the Shanghai region. We understand the hassle and additional costs associated with sourcing components from multiple suppliers. That's why we strive to be your one-stop solution, saving you time, money, and unnecessary stress.

Trust Triple-C for All Your Molding and Sourcing Needs

When you purchase molds from Triple-C in China, you gain access to our comprehensive sourcing expertise. Partner with us for a streamlined and cost-effective solution for all your injection molding, assembly part, and packaging requirements.